Nippon Felt recognizes that consideration for the environment, quality,

and society is essential for maintenance and development of our business,

and we are making various efforts.

- Promotion of corporate activities in harmony

with the global environment - We are actively working to set our own environmental policy and to comply with environmental laws and regulations.

Environmental policy

We recognize that addressing environmental issues is an essential requirement for maintaining and growing our business. Based on this recognition, we contribute to the reduction of environmental impact by providing papermaking equipment which directly aids productivity improvement and environmental consideration in the papermaking process.

In addition to complying with environmental laws and other requirements with which Nippon Felt agrees, we will strive to protect the environment and continuously improve our environmental management system with the aim of harmonizing our business activities with the environment.

- Objectives and major initiatives

-

1. Resource conservation

- Reduction of energy consumption rate

- Reduction of resource loss in the production process

- Reduction of chemical usage amount

- Promotion of waste recycling

2. Coexistence with local communities

- Consideration of living environment for nearby residents

- Participation in local environmental activities

- Initiatives to reduce environmental impact

- We are making the following efforts to operate in accordance with the environmental policy and environmental laws listed above.

1. Development and sales of environmentally-friendly products

Pursue optimal design for press felt

Improving the water squeezing properties of the press stage in the paper manufacturing process will significantly reduce the energy used for drying in the drying stage.

We will contribute to reduced energy consumption in the papermaking process by pursuing optimal design for press felt used in the press stage.

Sale of original fabrics for bag filters

Original fabric for bag filters, which is an industrial textile product, is used to remove harmful substances emitted from garbage incinerators, etc., and contributes significantly to the preservation of the global environment.

2. Initiatives for promoting the spread of renewable energy

-

Initiatives for solar power generation

Since 2014, we have been working on solar power generation (low voltage) at the Saitama Mill and Tochigi Mill, which are our main production bases in Japan.

-

Promoting the spread of biomass power generation

By expanding sales of original fabric for bag filters for biomass boilers, we are contributing to the spread of biomass power generation, which is a renewable energy source.

3. Initiatives for reducing CO2 emissions

Nippon Felt is contributing to the preservation of the global environment by striving to meet reduction targets required by related ordinances.

-

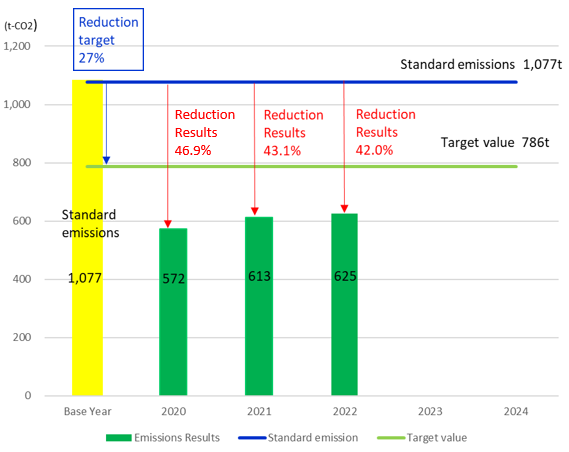

Efforts to reduce greenhouse gas emissions in accordance with the Tokyo Metropolitan Environmental Security Ordinance (FY2020 to FY2024)

- Head Office

-

- Reduction target: 27%

- Reduction results: 42.0%

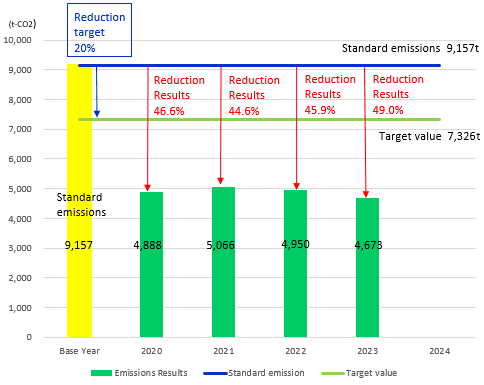

Initiatives to reduce greenhouse gases based on the Saitama Prefecture Global Warming Strategy Promoting Ordinance (FY2020 to FY2024)

- Saitama Mill

-

- Reduction target: 20%

- Reduction results: 45.9%

Cooperation with Zero Carbon Saitama The Saitama Mill has cooperated in reducing CO2 emissions by using the "target-setting Carbon emission trading system ".In January 2021, a letter of appreciation was awarded by Saitama Prefecture in recognition of our cooperation with Saitama Prefecture's initiative "Zero Carbon Saitama."

- Quality initiatives

- We are working to improve quality and establishing our own quality policies.

Quality policy

All employees of our company will work together to continuously provide high-quality papermaking tools, and will aim to become a comprehensive paper machine tool company that is always trusted by customers.

- Main initiatives

-

- Steady support for customers' production activities

- Pursuit of optimal product design

- Expansion of product lineup

- Reliable succession of cultivated manufacturing technology

- Principle of safety first

- Promotion of maintenance of manufacturing equipment

- Promotion of business improvement

- Initiatives for safety and security/Coexistence with society

- We are implementing the following initiatives in pursuit of even better products and society.

1. Creation of high-quality products

Quality control initiatives

We implement thorough quality control through raw material acceptance inspection, compliance with work standards, process management, and product inspection. Since many of our products are made-to-order designs according to the customer's usage situation, we are particularly focused on product inspection. In addition to using machines to measure physical properties, human technicians also perform visual inspection of external appearance, tactile inspection, etc.

Quality improvement initiatives

- Our technical department is working to improve the next designs by performing product analysis during and after use. Additionally, based on the customer needs collected by the technical department, the R&D department promotes new product development and aims to create even better products.

- As a bottom-up improvement activity, we are making company-wide efforts for QC circle activities. We have company-wide competiton, every year. Through this culture of friendly competition, we work together in pursuit of even higher quality.

Stabilization of supply

We are approaching the stabilization of supply from the two aspects that raw material procurement and manufacturing. Risks in raw material procurement are reduced by adopting a multiple sourcing strategy, strengthening cooperation with raw material manufacturers, and optimizing inventory stockpiling. We make sure that manufacturing is not delayed by thorough training of workers, maintenance of production facilities, process control, and delivery date control.